Every year, over 1,000 generic drugs get approved by the FDA - drugs that save Americans billions and make prescriptions affordable. But how do they actually get approved? It’s not magic. It’s a strict, science-backed process called the Abbreviated New Drug Application (ANDA). And if you’re trying to bring a generic drug to market, you need to know every step - or risk years of delays and millions in wasted costs.

What Is the ANDA Process?

The ANDA process is the legal pathway for generic drug manufacturers to get FDA approval without repeating all the expensive clinical trials done by the original brand-name drug maker. It was created by the Hatch-Waxman Act of 1984. The goal? Let safe, effective generics hit the market faster and cheaper - which they do. Today, 90% of all prescriptions filled in the U.S. are generics, but they cost just 23% of what brand-name drugs do.

Unlike a New Drug Application (NDA), which requires full safety and efficacy data from scratch, an ANDA only needs to prove one thing: your drug works exactly like the brand-name version. That’s it. No new clinical trials on patients. No animal studies for safety. Just proof you’re the same.

Step 1: Identify the Reference Listed Drug (RLD)

You can’t just pick any brand-name drug to copy. You have to match a specific one that’s already FDA-approved - called the Reference Listed Drug, or RLD. The RLD is listed in the FDA’s Orange Book, which tracks approved drugs and their therapeutic equivalence ratings.

For example, if you want to make a generic version of Lipitor (atorvastatin), you must use the exact same active ingredient, strength, dosage form, and route of administration as the RLD. You can’t change the tablet size, skip the extended-release coating, or switch from oral to injection. If you do, it’s not a generic anymore - it’s a new drug, and you’re back to an NDA.

Also, the RLD must not be under patent or exclusivity protection. If the brand still has 180-day exclusivity or a patent hasn’t expired, your ANDA can’t be approved yet - even if everything else is perfect.

Step 2: Prove Pharmaceutical Equivalence

Pharmaceutical equivalence means your drug is chemically identical to the RLD in three ways:

- Active ingredient - same compound, same salt form, same purity

- Strength - same dosage per unit (e.g., 20 mg tablet)

- Route of administration - same way it enters the body (oral, injection, inhaler, etc.)

You also need to show your inactive ingredients - things like fillers, dyes, preservatives - are safe and don’t affect how the drug works. The FDA doesn’t require them to be identical, but they must be non-toxic and not interfere with absorption. If your tablet uses a different dye than the brand, that’s fine - as long as it doesn’t cause an allergic reaction or alter stability.

Manufacturers submit detailed chemistry, manufacturing, and controls (CMC) data. This includes:

- Drug substance synthesis and purification methods

- Drug product formulation and process controls

- Specifications for raw materials and finished product

- Stability testing under real-world conditions (temperature, humidity, light)

Failure here is the #1 reason ANDAs get rejected. About 32% of Complete Response Letters (CRLs) from the FDA cite CMC issues - often because the manufacturer didn’t control particle size, impurity levels, or dissolution rates properly.

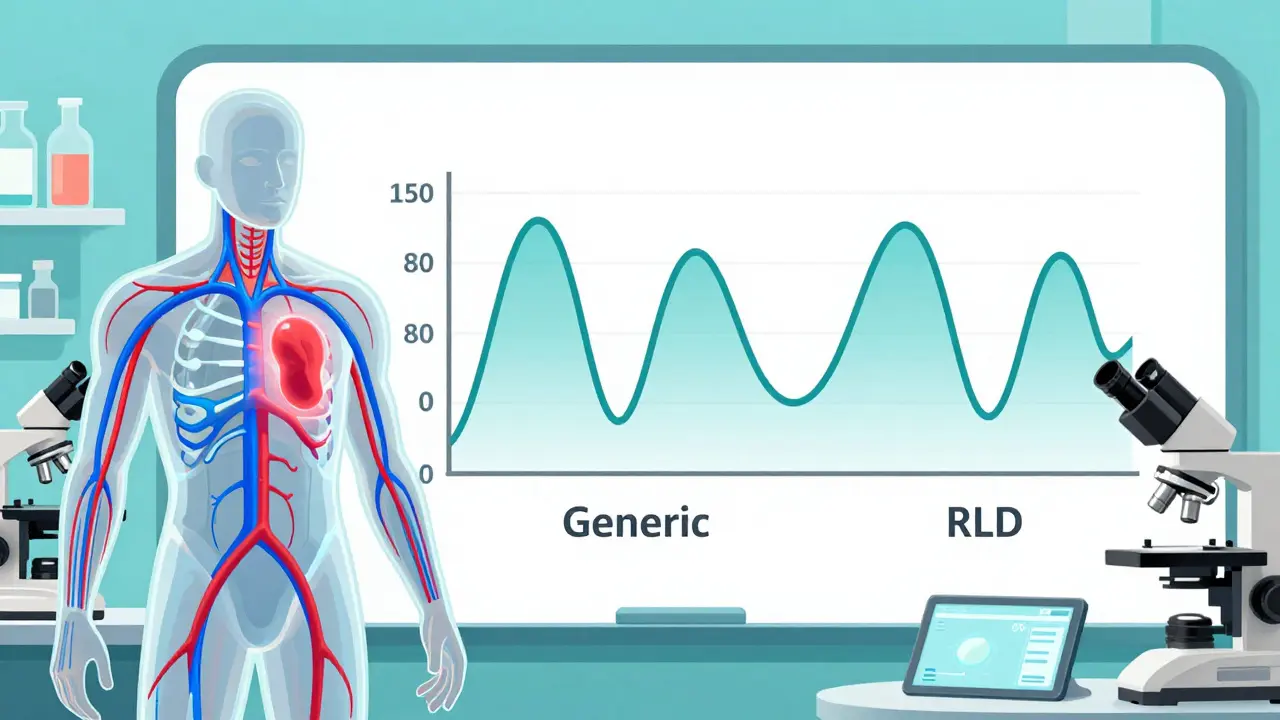

Step 3: Demonstrate Bioequivalence

This is the heart of the ANDA. Bioequivalence means your generic delivers the same amount of active ingredient into the bloodstream at the same rate as the brand-name drug.

To prove this, you run a bioequivalence study - usually with 24 to 36 healthy volunteers. Each person takes both your drug and the RLD on separate occasions, with a washout period in between. Blood samples are taken over 24-72 hours to measure how much drug is absorbed and how fast.

The FDA requires your drug’s rate and extent of absorption to fall within 80-125% of the RLD’s values. That’s not a guess - it’s a strict statistical range. If your drug hits 126%, it’s not bioequivalent. No approval.

For complex products - like inhalers, topical creams, or extended-release tablets - the rules get tougher. The FDA has special guidance for over 27 complex drug types. A nasal spray, for instance, might need aerosol particle size testing, in vivo studies, or even human pharmacodynamic studies. These can cost over $2 million and take years to complete.

Step 4: Submit the ANDA in eCTD Format

You can’t just email a PDF. The FDA requires all ANDAs to be submitted electronically in the electronic Common Technical Document (eCTD) format. This is a standardized structure with five modules:

- Module 1 - Administrative information (applicant details, certifications, fees)

- Module 2 - Summaries (quality, nonclinical, clinical)

- Module 3 - Quality data (CMC details)

- Module 4 - Nonclinical study reports

- Module 5 - Clinical study reports (bioequivalence data)

Each section has strict formatting rules. A misplaced table, a missing signature, or a file named wrong can trigger a filing review failure. The FDA has 60 days to decide if your ANDA is complete enough to even start reviewing. If not, you get a Refuse to Receive letter - and you start over.

Step 5: FDA Review and Inspection

Once your ANDA is accepted, the clock starts. Under GDUFA IV (2023-2027), the FDA aims to review 90% of original ANDAs within 10 months. The average is now around 10-12 months.

The review team includes scientists from pharmacology, chemistry, manufacturing, and labeling. They check every page. If they find a gap - say, your bioequivalence study didn’t include enough subjects - they send an Information Request (IR). You have 15-30 days to respond. Miss the deadline? Your application stalls.

Meanwhile, the FDA inspects your manufacturing site. Even if you’re outsourcing production, every facility - whether in the U.S., India, or China - must pass cGMP (current Good Manufacturing Practices). The FDA doesn’t just check paperwork. They send inspectors to walk through your factory, watch your machines, and test samples on the spot.

Over 22% of ANDA rejections are tied to facility issues: poor sanitation, uncalibrated equipment, or inconsistent batch records. One company lost $1.8 million after their Chinese plant failed inspection because a temperature log was missing for 11 days.

Step 6: Approval or Complete Response Letter (CRL)

At the end of the review, you get one of two outcomes:

- Approval - Your drug is now legally marketable. You can start selling.

- Complete Response Letter (CRL) - The FDA says, “Not yet.” They list every deficiency. You fix them and resubmit.

About 75% of ANDAs get approved on the first try. The other 25% get a CRL. Common reasons:

- Incomplete bioequivalence data (28%)

- CMC deficiencies (32%)

- Manufacturing site problems (22%)

- Labeling mismatches with the RLD (18%)

Some companies get multiple CRLs. One applicant spent 28 months and $2.3 million on a nasal spray that got three CRLs - each time over different bioequivalence methods.

Step 7: 180-Day Exclusivity (If You’re First)

If you’re the first company to file an ANDA challenging a patent (via Paragraph IV certification), you get 180 days of market exclusivity. No other generic can enter during that time.

This is huge. In 2023, the first generic version of Humira earned over $1.2 billion in sales during its exclusivity window. But it’s risky. If you lose a patent lawsuit, you lose exclusivity. Many companies get caught in legal battles that delay entry for years.

What Happens After Approval?

Approval isn’t the finish line. The FDA still monitors your drug. You must report adverse events. You must maintain cGMP compliance. You must notify the FDA before changing your manufacturing process - even slightly.

And if your drug is found to be unsafe or inconsistent? The FDA can pull it from the market. In 2022, 12 generic drugs were recalled for failing dissolution tests or containing impurities above limits.

Who Can Do This?

You don’t need to be a giant pharma company. But you do need expertise. The average ANDA takes 11-19 months to prepare before submission. You need:

- Regulatory affairs specialists

- Formulation scientists

- Bioanalytical labs

- Quality assurance teams

- Legal counsel for patent issues

Smaller companies often outsource parts of this - but they still need someone who knows the rules inside out. The Regulatory Affairs Professionals Society says it takes 18-24 months to train a new professional to handle an ANDA properly.

Why This Matters

Generic drugs save the U.S. healthcare system $373 billion every year. That’s not just money. It’s access. It’s a diabetic who can afford insulin. A heart patient who doesn’t skip doses because of cost. A senior on a fixed income who can keep taking their meds.

The ANDA process isn’t easy. It’s complex, expensive, and unforgiving. But it works. It’s how 90% of prescriptions get filled at a fraction of the cost. And as long as the FDA keeps improving it - with faster reviews, better tools, and clearer guidance - more people will get the medicines they need.

So let me get this straight - we’re talking about a $373 BILLION savings system that’s held together by half a dozen scientists in a basement in Maryland? The FDA reviews an ANDA like it’s judging a TikTok dance challenge - one wrong step and you’re out. And don’t even get me started on the 22% rejection rate because someone forgot to log a temperature for 11 days. This isn’t regulation. This is performance art with a lab coat.

The ANDA process, though complex, reflects a commendable balance between innovation and safety. It ensures that affordable medications reach patients without compromising quality. The structured approach, especially the bioequivalence standards, is a global benchmark. Countries like India have leveraged this framework to become leaders in generic manufacturing, benefiting millions worldwide.

Honestly? The real hero here is the guy in Bangalore who’s running HPLC at 3 a.m. because the batch failed dissolution. Nobody sees them. But without them, your $4 insulin doesn’t exist. The FDA’s process is brutal - but it’s the reason your generic works. Don’t hate the system. Hate the people who think it’s broken when they just don’t wanna pay for the R&D.

We think we want cheap medicine. But we don’t want to pay for the infrastructure that makes it possible. The ANDA isn’t a loophole. It’s a bridge. And someone has to walk it. Every day.

The eCTD format is just corporate bureaucracy dressed up as science. You spend 6 months formatting a PDF so the FDA won’t throw it out and then they ask for a new version because the font was 11.01 instead of 11.00. This isn’t medicine. This is a bureaucratic obstacle course with a side of placebo

So we spend 2 years and 2 million bucks to make a pill that looks exactly like the original and works the same way... and the brand name company still makes more money? I’m not mad. I’m just impressed by the sheer absurdity

okay so like i was reading this and i was like wait wait wait so if your factory in india has a temp log missing for 11 days they just say nope no drug for america?? like what?? 😭 i mean i get it but also?? why do we even have this system?? its like the FDA is a dragon guarding a treasure chest of pills and you gotta do 17 dances to get one 🐉💊 #genericdrugstruggles

The rigor of the ANDA process is not merely procedural; it is a moral imperative. In a world where pharmaceutical integrity is increasingly commodified, the FDA’s standards safeguard public trust. The meticulousness in CMC, bioequivalence, and manufacturing compliance ensures that the generic drug in your hand is not a compromise - but a confirmation of therapeutic equivalence.

imagine spending 28 months on a nasal spray and getting 3 CRLs… i mean… congrats?? 🤡 i just want my asthma med to work, not become a PhD thesis